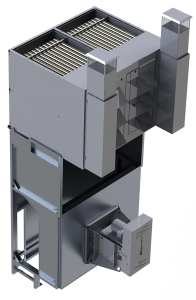

Each zone features a heat recovery vent system, harnessing energy lost during the drying process to preheat incoming air. This reduces fuel consumption by at least 15%, making it one of the most energy-efficient continuous kilns available.

Welcome to the forefront of wood drying technology. At Nyle Systems, we're proud to introduce the ProDRY High-Temperature Continuous Kilns, a leap forward in energy efficiency, sustainability, and advanced drying technology. Engineered with precision to meet the demanding needs of modern wood processing, ProDRY represents our commitment to innovation, offering unmatched performance, reduced energy consumption, and unparalleled quality in wood drying. Join us as we explore the features that set ProDRY apart, paving the way for a more efficient, sustainable future in wood drying.

Each zone holds a capacity of approximately 40,000 BF, maximizing efficiency and throughput.

The "Zero Footprint" Control Room is conveniently positioned above the kiln for easy access and operation.

Kiln Doors on both ends of the kiln ensure hassle-free loading and unloading.

Independent Zones allow simultaneous drying of different species at temperatures up to 260°F, providing versatile drying options.

Optional Automated kiln cart return system available for effortless cart handling after unloading.

Elevate your lumber drying process with the ProDRY Kilns - a game-changer in energy efficiency and performance. Choose Nyle for the most innovative, flexible, and cost-effective drying solution for your business.